Social Initiatives through

Corporate Activities

We cherish our irreplaceable earth, and voluntarily and proactively engage in environmental conservation activities in all phases of our corporate activities.

We cherish our irreplaceable earth, and voluntarily and proactively engage in environmental conservation activities in all phases of our corporate activities.

We cherish our irreplaceable earth, and voluntarily and proactively engage in environmental conservation activities in all phases of our corporate activities.

The OHARA Group has set one of its top management priorities as caring for the irreplaceable Earth, in other words, harmony with the global environment. The Group as a whole is working together with its business partners on environmental activities.

OHARA inc. will practice sustainability management to become a 100-year company, share our vision and strategy with related stakeholders based on the OHARA Value Creation Model, and open up the future by creating new values co-creation to address social and environmental issues. We will also realize carbon neutrality as a key management issue to realize a sustainable well-being of our planet.

November 1, 2025.

President Chief Executive Officer

Hirokazu Saito

OHARA has set ISO14001 (environmental management system) as the objective to harmonize corporate activities with the global environment, and is promoting various efforts under the Environmental Policy.

In addition to compliance with laws and regulations, we will make groupwide efforts to reduce greenhouse gas (GHG) emissions in response to climate change, reduce waste in consideration of biodiversity, promote recycling, and use resources efficiently.

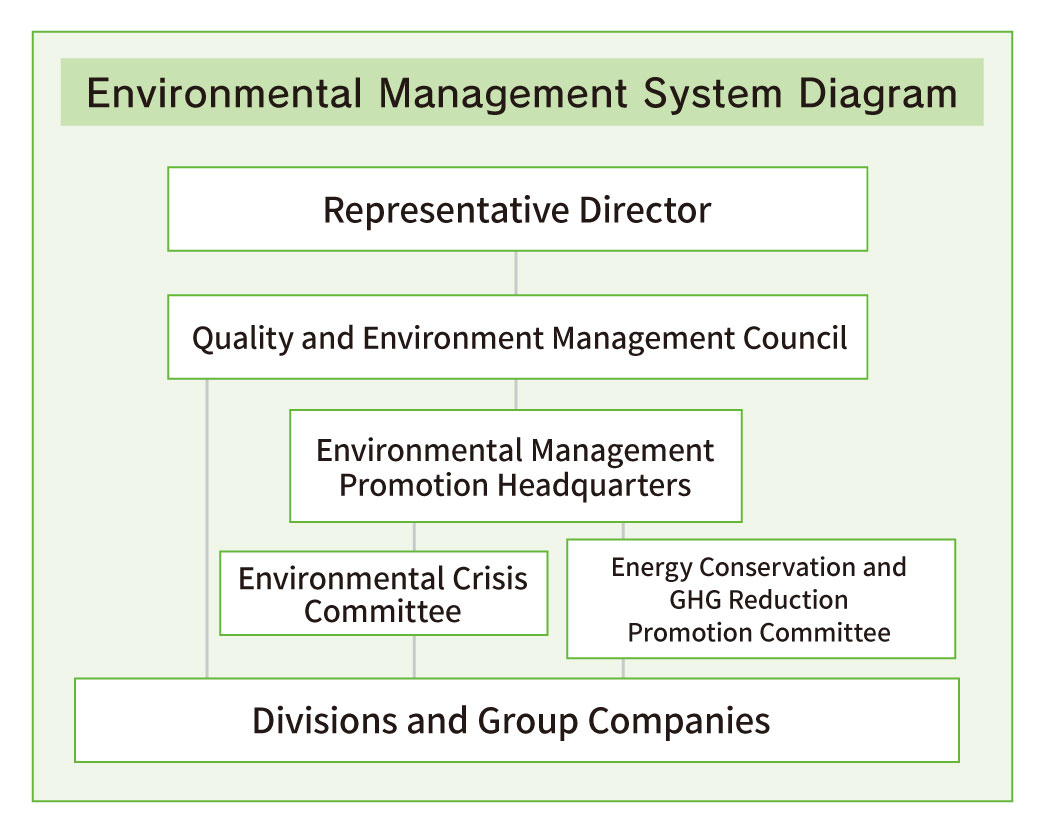

All OHARA Group companies are working as one to promote a variety of activities with the philosophy and policies for environmental management, aiming at harmony between corporate activities and the global environment. In FY2022, certain part of OHARA’s environmental management promotion system was expanded to include the entire group, and the Energy Conservation and GHG Reduction Committee was established to strengthen the Group’s system for addressing environmental issues, particularly the reduction of greenhouse gas (GHG) emissions.

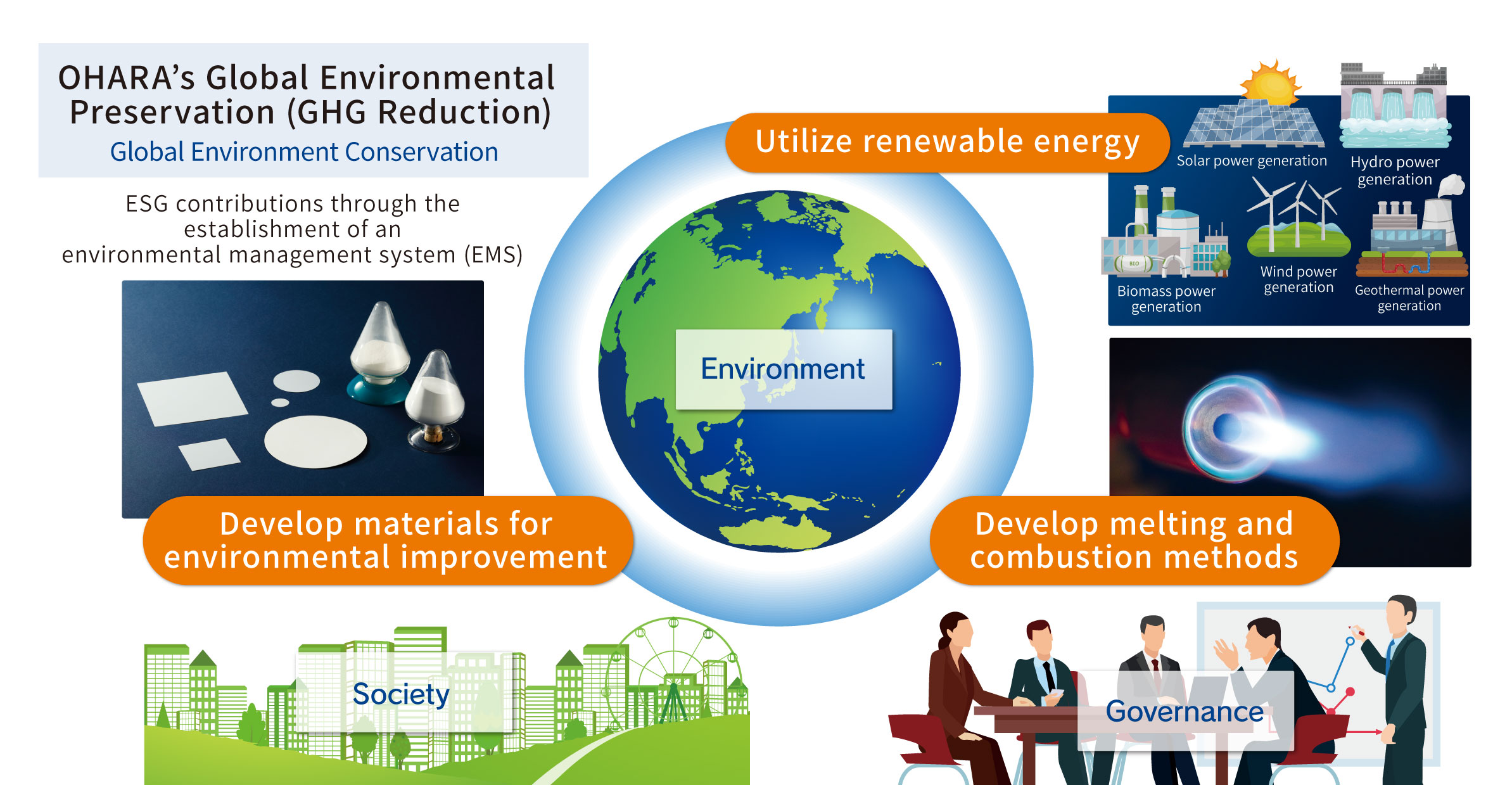

The OHARA Group discusses climate change-related effects such as global warming and increased frequency of natural disasters, energy issues, and other environmental concerns, and works as one to address these challenges. In particular, we recognize the global warming phenomenon as a major issue with regard to climate change. The volume of greenhouse gas (GHG) emissions during the glass melting process, which consumes a large volume of energy in the production process, is an issue when it comes to preserving the global environment.

In response to this issue, the OHARA Group is working on measures to counter climate change centered on three perspectives: environment, social, and governance.

➀ Environment

To help protect the global environment, we are utilizing renewable energy and developing more efficient melting and combustion methods as well as materials for environmental improvement.

➁ Social

Global climate change has started to dramatically affect the lives of people in society and the activities of companies. We are pursuing sustainability management while also seeking to harmonize our activities with society.

③ Governance

We monitor the Group’s implementation of climate change initiatives.

The OHARA Group has established and regularly monitors metrics for evaluating the effectiveness of its actions regarding the global climate change risks and opportunities it has identified.

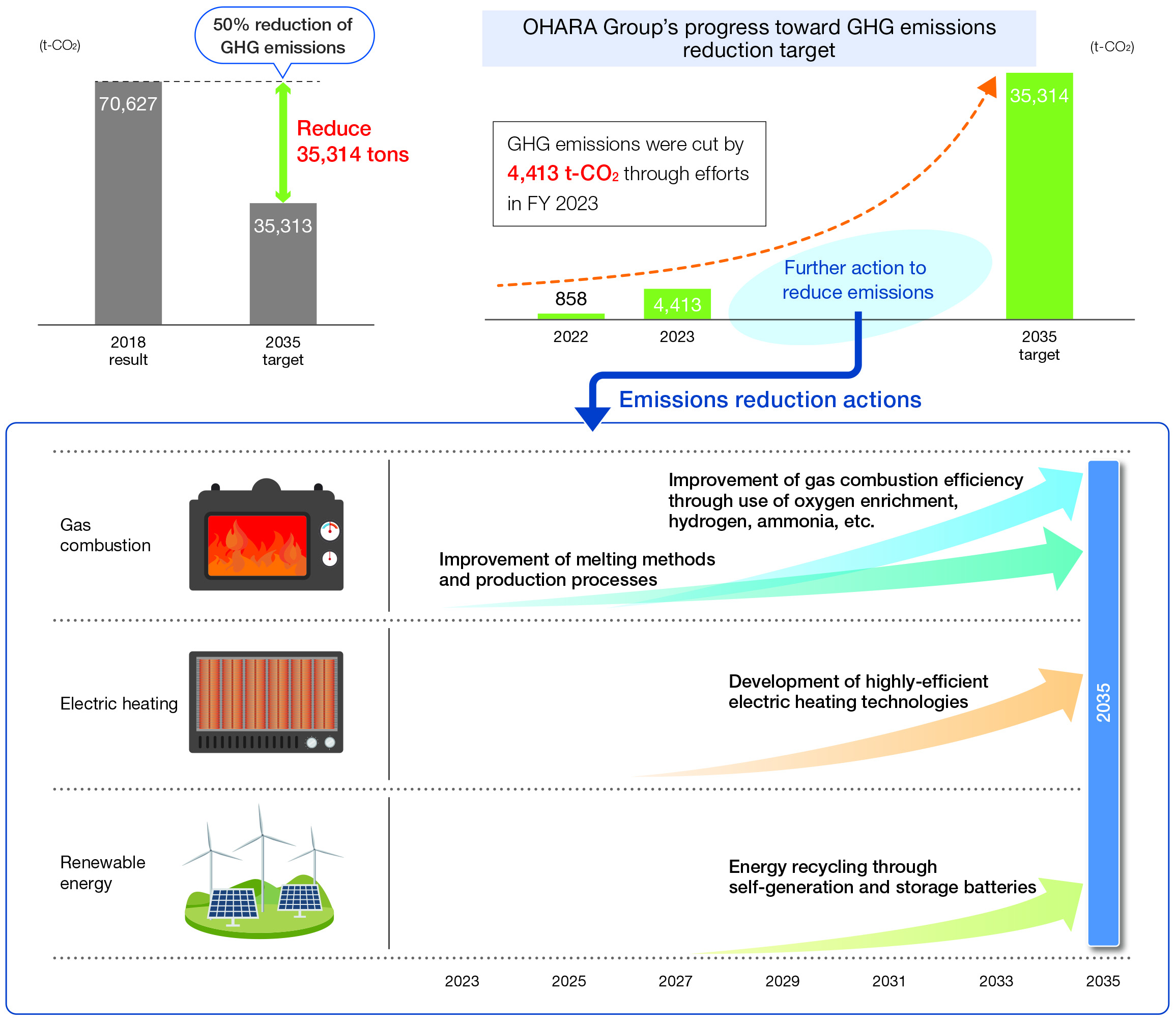

As a step toward achieving carbon neutrality, we are working to reduce our GHG emissions generated mainly in the energy-intensive glass melting processes. In order to realize the Long-Term Vision 2035 and our Environmental Policy of maintaining the sustainable wellbeing of our planet, we will lower our GHG emissions by 50% (versus FY 2018) by 2035.

In addition, we recognize the enormous environmental impact of GHG emissions associated with the import/export of materials, semi-finished product, and products, as well as the use of heating equipment in melting and processing processes. Accordingly, we have made Group-wide GHG emissions one of the key metrics we monitor. This includes not only Scope 1 and 2 emissions (from the use of gas and electricity), but also some Scope 3 emissions (from inter-site transport, etc.).

OHARA is developing technologies for lowering GHG emissions through improved efficiency in gas combustion and melting, including technologies for oxygen-enriched combustion and thermal insulation. We are also considering possibilities for future development of combustion technologies that do not emit CO², such as combustion of hydrogen or ammonia. With regard to electric heating, we are utilizing melting technology with high heating efficiency accumulated over many years, as well as renewable energy with self-generation, storage batteries, and other systems, and are promoting modal shift in product transport. In order to make this a reality, we are developing human capital, including energy and environment engineers, in our aim to achieve our 2035 GHG emissions reduction targets.

●Development of energy efficiency technologies for combustion and electric power

●Switching transport equipment and company cars to electric vehicles (EVs)

●Modal shift in product transport(installation of solar panels, etc.)

●Switching electrical equipment, air conditioning, and lighting to energy-saving models

●Utilization of renewable energy

●Utilize the Group’s production sites to make use of national and regional measures against greenhouse gas (GHG) emission in production processes.

●We aim to establish a global network that contributes to streamlining and greenhouse gas (GHG) reduction throughout the entire supply chain, taking into account the characteristics of each site, including raw material procurement and outsourced processing.

In order to increase the reliability of our disclosures on non-financial information such as GHG emissions reduction efforts, we undergo third-party verification by LRQA regarding the Scope 1 and 2 emissions of our Group as a whole and outsourced melting operations, and the calculated amount of certain Scope 3 emissions from inter-site transport and other operations, and we disclose the results to our stakeholders. In 2023, we received verification statements for our head office, Obtain a Third-party Verification Statement two domestic sites, and two overseas sites. We will continue expanding third-party verification to other sites and taking steps to further improve the reliability of our data.

The “Act on Promotion of Resource Circulation for Plastics” was enacted in April 2022 to address the environmental impact of the increasing amount of marine plastic waste. In OHARA’s head office operations, 25% of the 60 tons of plastic waste generated annually is converted to material recycling for use in recycled plastic products.

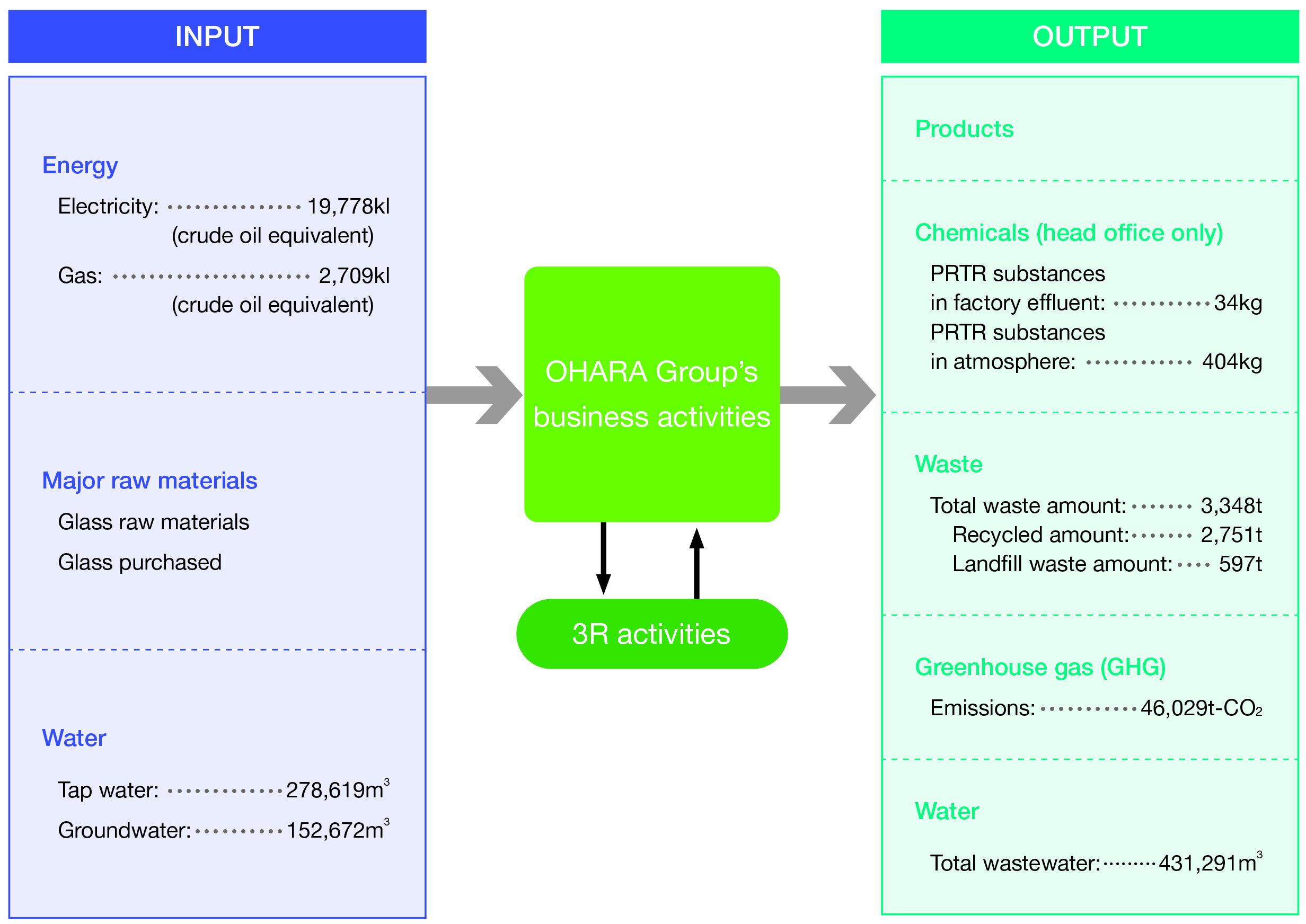

The OHARA Group develops environmental conservation activities by quantitatively measuring the amount of energy and resources used in its business activities (INPUT), as well as the products and environmental loads generated by those activities (OUTPUT).

In April 2000, OHARA obtained certification under the international ISO14001 standard for environmental management (the certification body was JIC Quality Assurance Ltd.). We attained the environmental objectives and targets, and escalated environmental management systems through the Waste Reduction and Reuse Promotion Committee, the Resource Conservation Committee, the Energy Saving Promotion Committee, and environmental management activities at every department.

※The scope of application of the environmental management system is as follows. The environmental management system is applied to the head office and factory of OHARA INC. and its affiliated companies. ※In-house subcontractors collectively refer to contractors who are resident on our premises and who undertake the operations of our company or those who perform requested operations (repairs, maintenance services, etc.) within this factory.

Related information can be viewed by following the links below.

The things we focus on in manufacturing are explained.