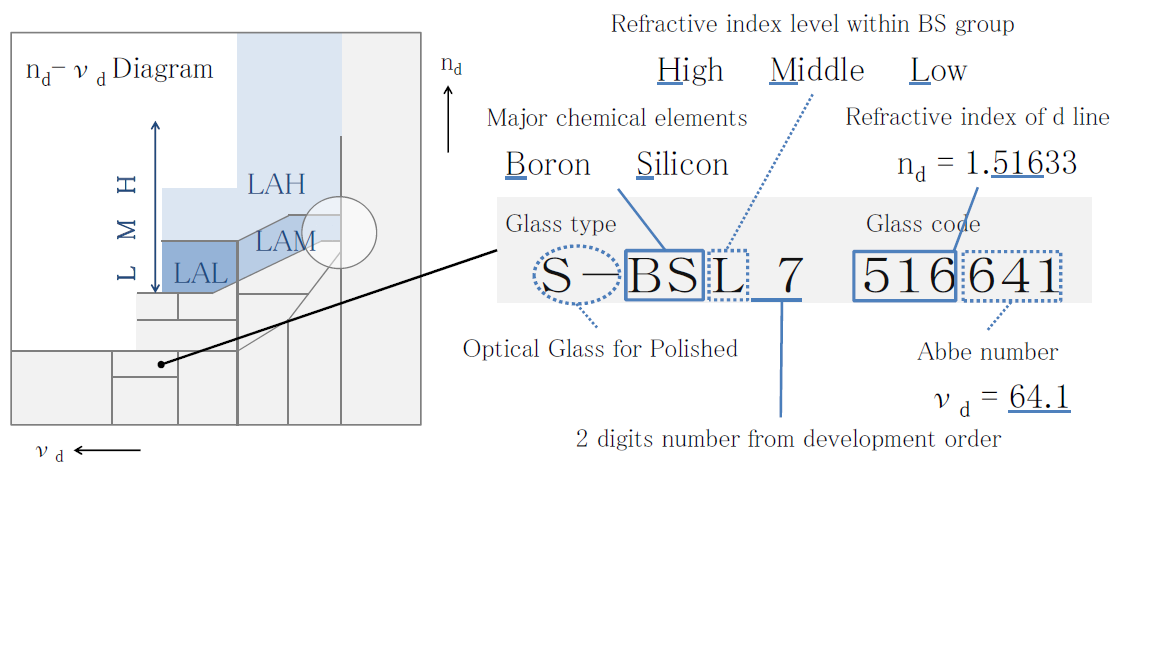

GUARANTEES OF QUALITY7.1 Refractive Index and Abbe Number

Refractive Index and Abbe Number

Refractive indices and Abbe number, which are given in this catalog, are

the representative value of plural melting lots. The values of the melting lot

delivered will be within the tolerances specified below:

[ Optical Glass for Polished Lenses ]

nd : ±30×10-5

νd : ± 0.5% (rounded up to the guaranteed number of digits)

Upon special request, and depending upon the glass types, the following

tolerances can be accepted :

nd : ±20×10-5

νd : ±0.3% (rounded up to the guaranteed number of digits)

In the supply of our standard products, Melt Data is attached and includes

the following data :

- Refractive indices: the measurement values of each spectral lines (C, d, F, g ).

These are shown to 5 decimal places. (effective number: six digits)

- Abbe numberνd: the calculated value by the measured refractive indices.

These are shown to 1 or 2 decimal places.

e.g. S-BSL7

nd : 1.51633 ± 0.00030

νd : 64.14 ± 0.33

For special requirements, other than what is mentioned above, please contact us.

[ Optical Glass for Glass Mold Lenses ]

RC value : Standard RC value± 30 (Raw material control value)

νd : ± 0.5% (rounded to the guaranteed number of digits)

When products are supplied, the RC value is given to Melt No..

This RC value is Δnd at 5 decimal places concerning the material that

underwent OHARA’s standard annealing (-600°C per day). The RC value is

rounded to 4 decimal places and shows with a unit of 10-5.

And it comes with a report of theνd value to 1 or 2 decimal places concerning the

product after annealing as specified in catalog annealing (-200°C per day).

e.g. L-BSL7

RC value : -30 ± 30

νd : 64.06 ± 0.33

The standard measurement accuracy for refractive index and dispersion is

as follows :

Refractive index : ±3×10-5

Dispersion : ±2×10-5

On request, we shall measure at precision accuracy as follows :

Refractive index : ±1×10-5

Dispersion : ±3×10-6

For ultra-precision measurements and reading at spectral lines not

described in this catalog, please contact us.

GUARANTEES OF QUALITY7.2 Homogeneity

Homogeneity

For glass used in very precise lens systems it is sometimes necessary to measure the refractive index variation across a blank. In such cases, Ohara pays special attention to each process and can supply high homogeneity glass. The homogeneity is measured by calculating PV value of refractive index fluctuation width (excluding linear change component of refractive index) using computer analysis of the transmitted wavefront of a planeparallel glass sample with the phase-measuring interferometer. In case that the value of the change amount (PV) must be guaranteed within 4×10-5, measurement of an individual product is conducted and the value of the change amount is guaranteed at six decimal places (10-6).

Note: The homogeneity of our general glass products could exceed PV (Range) 4×10-5, depending on glass type, dimensions, shape, etc.

GUARANTEES OF QUALITY7.3 Stress Birefringence

Stress Birefringence

In case that glass retains residual strain, this can be observed as optical birefringence.

The amount of stress is measured by optical path differences and specified in nm/cm.

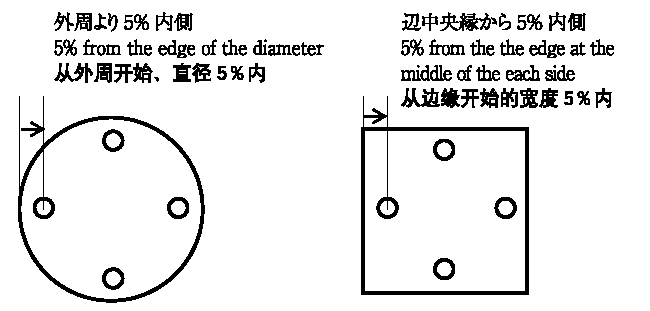

On special request, when we measure stress birefringence in detail,

a rectangular plate is measured 4 points located 5% from the edge at the middle of the each side.

A disc is measured at 4 points located 5% fromthe edge of the diameter.

The maximum value of the 4 points is shown as the birefringence value and is categorized based on Table 11.

For other special forms and shapes the points to be measured will be determined.

Table 11

| Class |

1 |

2 |

3 |

4 |

| Birefringence(nm/cm) |

<5 |

≧5 <10 |

≧10 <20 |

≧20 |

GUARANTEES OF QUALITY7.4 Striae

Striae

In case that glass retains residual strain, this can be observed as optical

birefringence.

The amount of stress is measured by optical path differences and specified

in nm/cm.

On special request, when we measure stress birefringence in detail, a

rectangular plate is measured 4 points loacated 5% from the edge at the

middle of the each side. A disc is measured at 4 points located 5% from

the edge of the diameter. The maximum value of the 4 points is shown as

the birefringence value and is categorized based on Table 11.

For other special forms and shapes the points to be measured will be determined.

Table 12

| Striae Class |

Striae Content Using Striaescope |

| 1 |

No visible striae |

| 2 |

Striae is light and scattered |

| 3 |

Striae is heavier than Class 2 |

GUARANTEES OF QUALITY7.5 Bubble & Inclusion

Bubble & Inclusion

It is most desirable to manufacture bubble-free optical glass, but the existence

of bubbles to some extent is inevitable. Bubbles in optical glass vary in size

and number from one glass to another due to the many different compositions

and production methods. The classification of bubble content is established

by specifying in mm

2 the total bubble cross sections existing in 100cm

3 of

glass volume. Inclusions such as small stones or crystals are treated as

bubbles. The bubble classes are shown in Table 13. The classification

includes all bubbles and inclusions measuring larger than 0.03 mm.

Table 13

| Class |

1 |

2 |

3 |

4 |

5 |

| 100cm3The total cross section of bubbles(mm2/100cm3) |

<0.03 |

≧0.03

<0.1 |

≧0.1

<0.25 |

≧0.25

<0.5 |

≧0.5 |

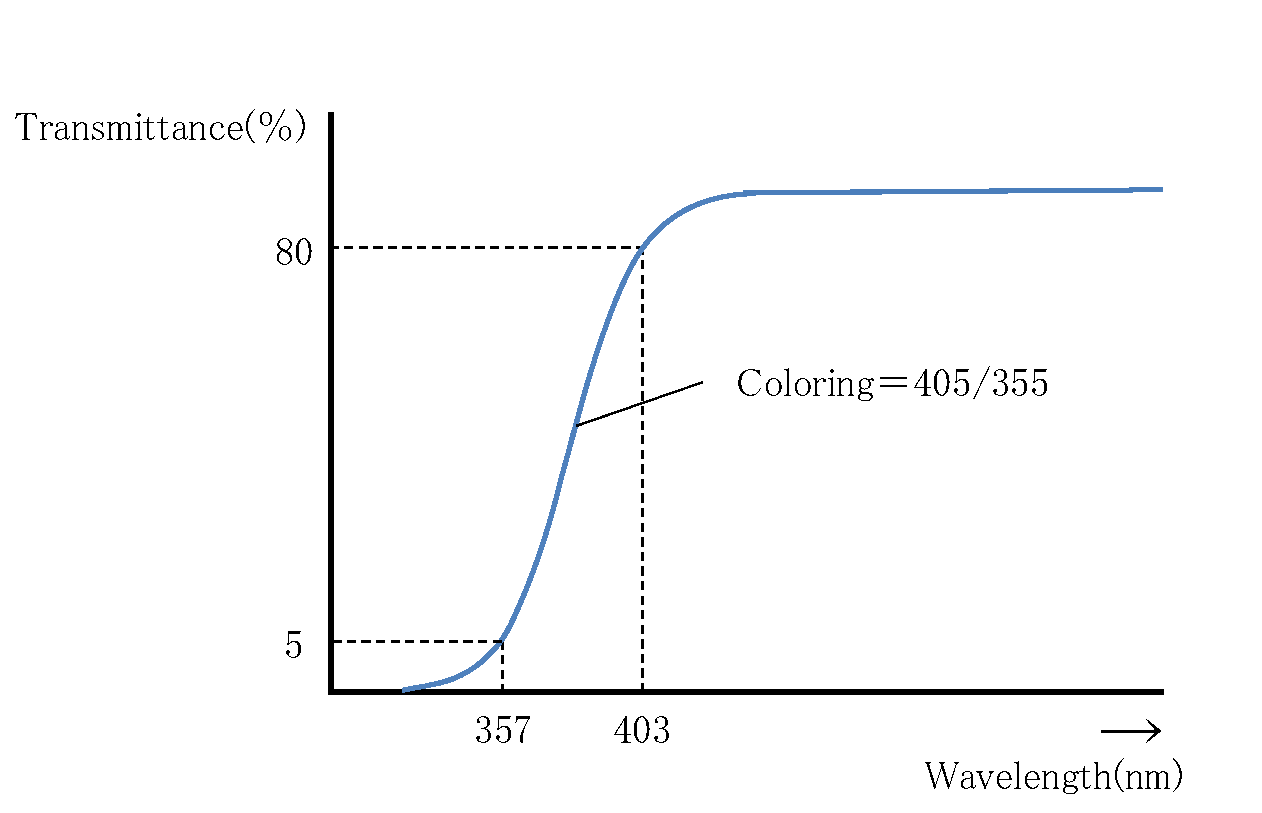

GUARANTEES OF QUALITY7.6 Coloring

Coloring

Variation of coloring between melting lots is generally within ±10 nm.

On special request, we shall report the coloring or the transmission, of the

melt to be supplied by measuring spectral transmission.

GUARANTEES OF QUALITY7.7 Others

Others

We showed each properties as representative value except for 7.1~7.6. Please

contact us when you want to know the other value. In addition, please let

us know your preferred specification when you place the orders.

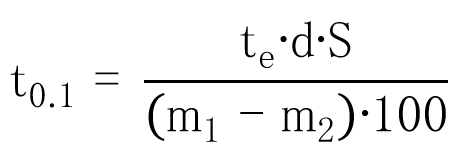

Calculation of the time(h) required in order to attack a surface layer to a depth of 0.1μm is done using the following formula:

Calculation of the time(h) required in order to attack a surface layer to a depth of 0.1μm is done using the following formula: