Social Initiatives through

Corporate Activities

We cherish our irreplaceable earth, and voluntarily and proactively engage in environmental conservation activities in all phases of our corporate activities.

We cherish our irreplaceable earth, and voluntarily and proactively engage in environmental conservation activities in all phases of our corporate activities.

We cherish our irreplaceable earth, and voluntarily and proactively engage in environmental conservation activities in all phases of our corporate activities.

OHARA has set one of its top management priorities as caring for the irreplaceable Earth, in other words, harmony with the global environment. OHARA and its Group companies and business partners are actively working together.

OHARA inc. will practice sustainability management to become a 100-year company, share our vision and strategy with related stakeholders based on the OHARA Value Creation Model, and open up the future by creating new values co-creation to address social and environmental issues. We will also realize carbon neutrality as a key management issue to realize a sustainable well-being of our planet.

November 1, 2023.

President Chief Executive Officer

Hirokazu Saito

OHARA has set ISO14001 (environmental management system) as the objective to harmonize corporate activities with the global environment, and is promoting various efforts under the Environmental Policy.

In addition to compliance with laws and regulations, we will make groupwide efforts to reduce greenhouse gas (GHG) emissions in response to climate change, reduce waste in consideration of biodiversity, promote recycling, and use resources efficiently.

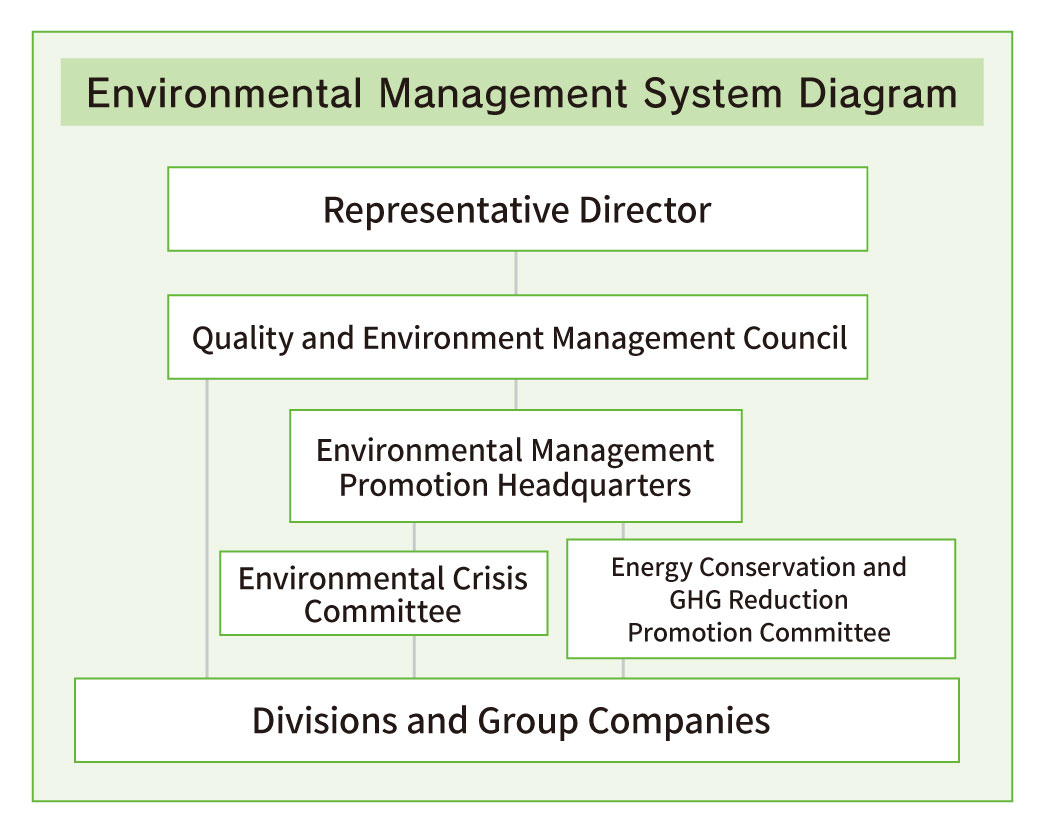

All OHARA Group companies are working as one to promote a variety of activities with the philosophy and policies for environmental management, aiming at harmony between corporate activities and the global environment. In FY2022, certain part of OHARA’s environmental management promotion system was expanded to include the entire group, and the Energy Conservation and GHG Reduction Committee was established to strengthen the Group’s system for addressing environmental issues, particularly the reduction of greenhouse gas (GHG) emissions.

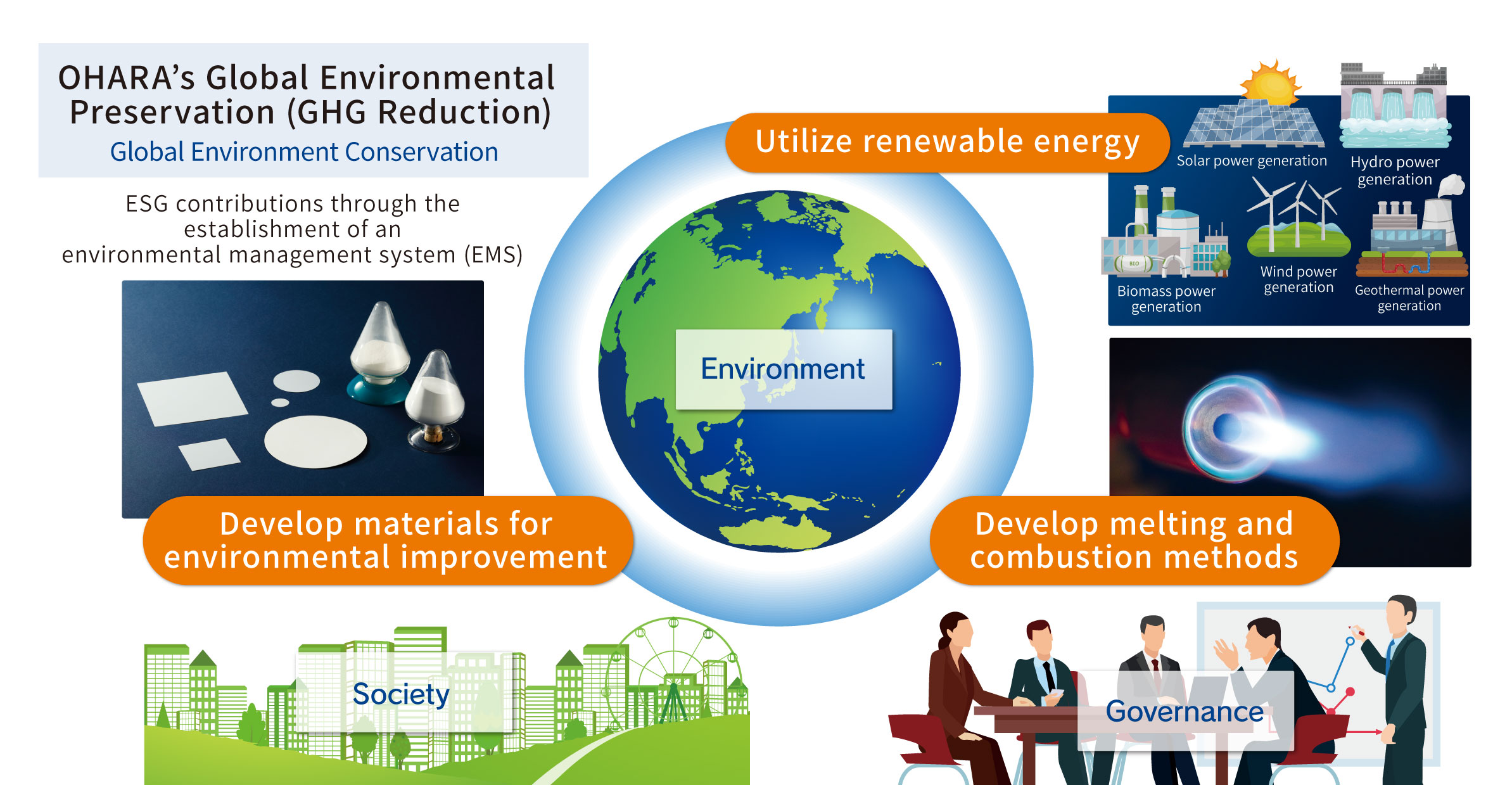

Reduction of greenhouse gas (GHG) emissions is a major challenge in glass manufacturing, which consumes a large amount of energy. OHARA is working hard on development of the technologies to increase energy efficiency through the use of special precious metals, which is unprecedented in optical glass production. We believe that producing optical glass at temperatures above the limit of general optical glass melting may lead to technological innovation for our customers, not only from an environmental standpoint, but also through the discovery of new materials and increased efficiency

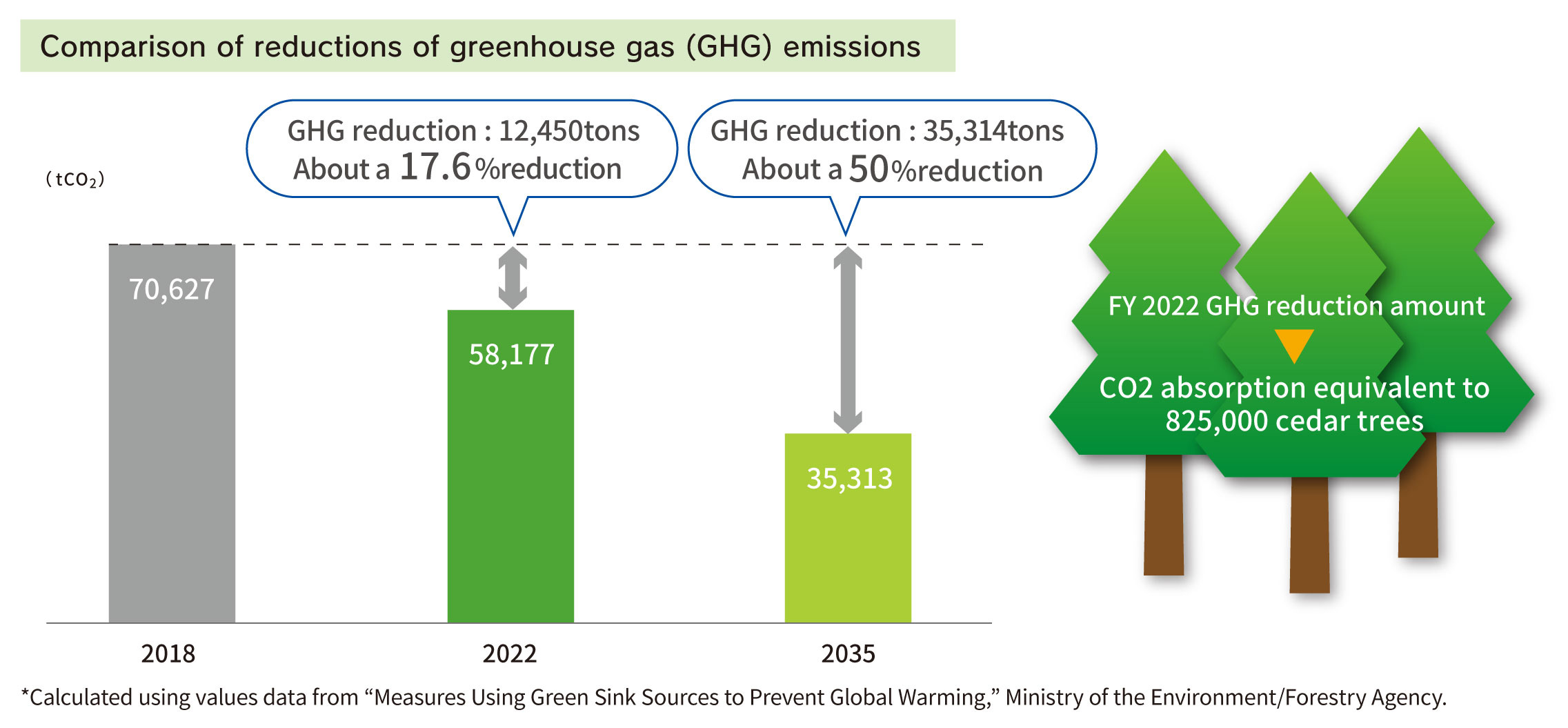

As international efforts to become carbon neutral grow, OHARA will reduce emissions of greenhouse gases (GHG), including carbon dioxide, generated from the melting of materials in the Company. We will work to reduce greenhouse gas (GHG) emissions by 50% (compared to FY 2018) by 2035, toward achieving the “sustainable well-being of our planet,” which is the society and the future OHARA desires, as set forth in the Long-term Vision 2035 formulated in FY 2021.

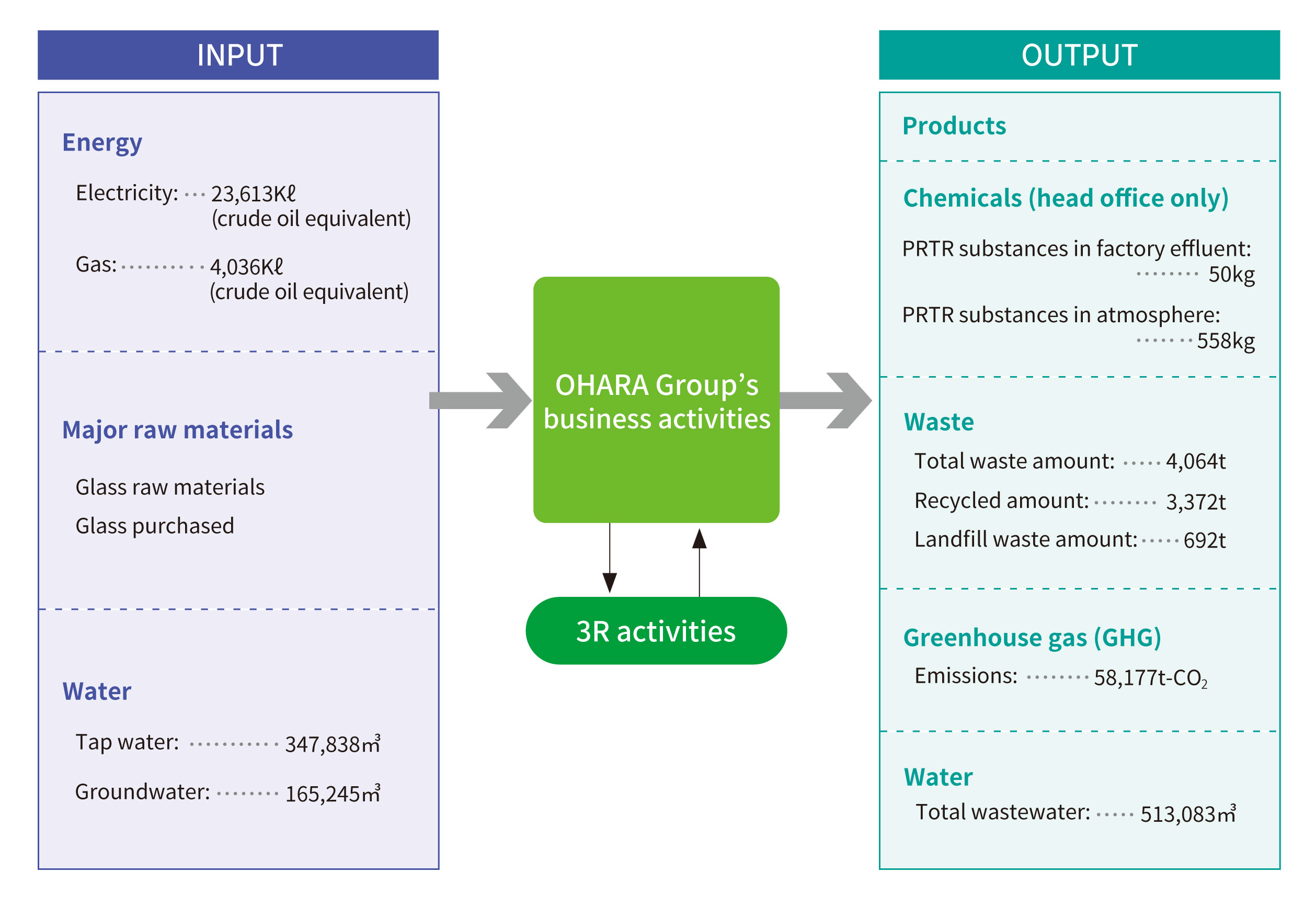

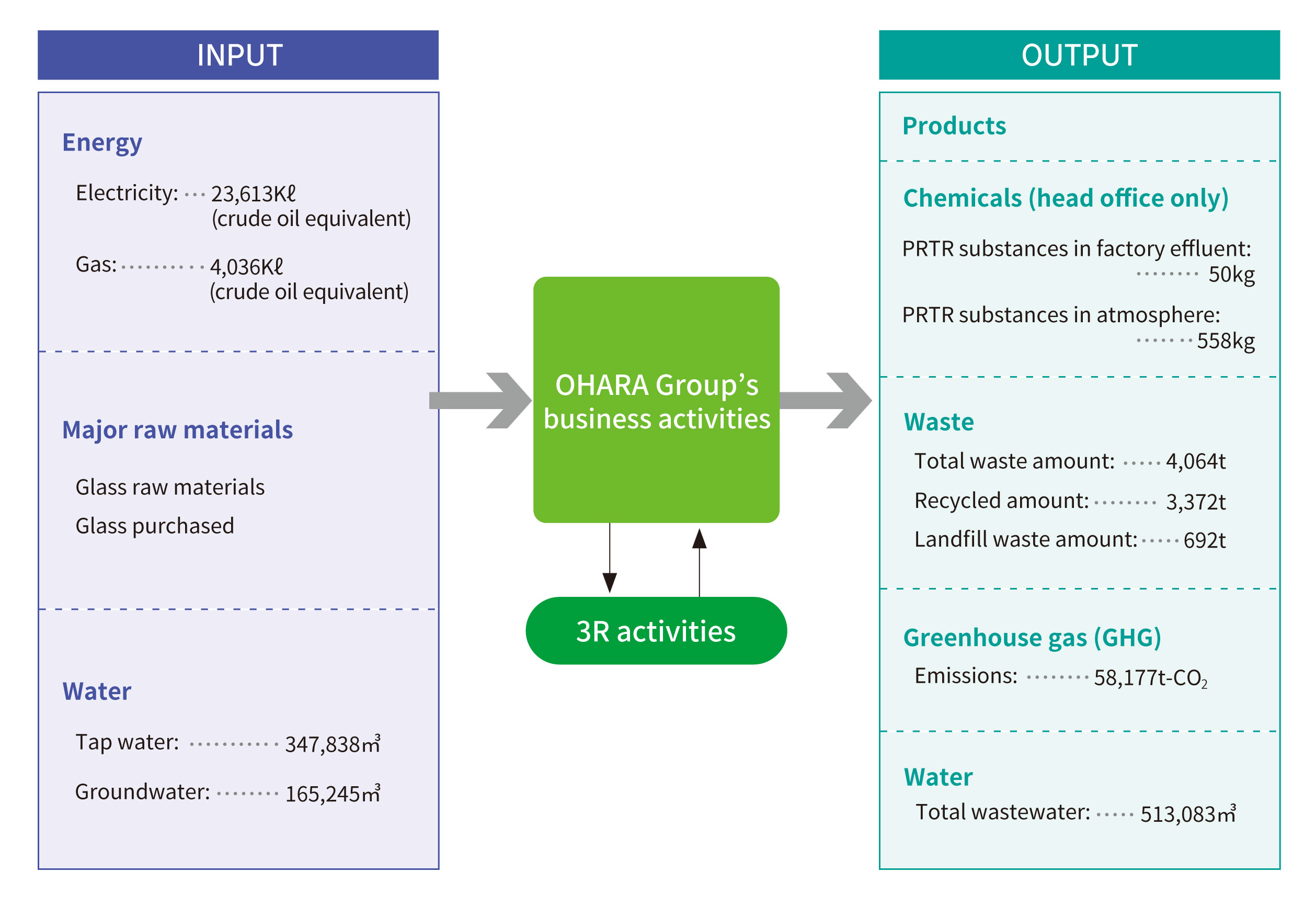

Overall emissions in FY 2022 were 58,177 tons, a 17.6% reduction compared to FY 2018.

*Includes outsourcing of melt processing, which is classified as Scope 3, Category 1, and transportation between Group bases in Category 4

●Reducing electricity consumption through technological development for melting methods

●Reducing greenhouse gas (GHG) emissions in society through development of eco-friendly materials

●Switching power use to renewable power

●Installing solar panels

●Switching air conditioning and lighting equipment etc. to energy-saving commercial products

●Promoting a modal shift in transportation activities for materials, processed goods, products, etc.

●Utilize the Group’s production sites to make use of national and regional measures against greenhouse gas (GHG) emission in production processes.

●We aim to establish a global network that contributes to streamlining and greenhouse gas (GHG) reduction throughout the entire supply chain, taking into account the characteristics of each site, including raw material procurement and outsourced processing.

In all business activities, we will work to reduce emissions even at affiliated companies that emit relatively large amounts of GHG emissions, and promote modal shifts in transportation activities for materials, processed goods, etc., to promote the reduction of greenhouse gases.

Of the total GHG emissions of 58,177 t-CO2 in fiscal 2022, 29,275 t-CO2 (Scope 1 and 2 covered) of the head office and domestic consolidated subsidiaries were verified by a third party by LRQA Limited.

| Scope1 | Use of fuels such as gas, emissions from factory processes |

|---|---|

| Scope2 | Use of electricity supplied by other companies |

| Scope3 | Manufacture of raw materials, etc. by processing and procurement companies Transportation of products and merchandise, sales, business trips, and commuting |

The final waste disposal rate in FY2022 was 26%. Glass that is no longer needed in production is being recycled (as base course material), but some of it is being disposed of in landfills. We will continue to promote waste red.

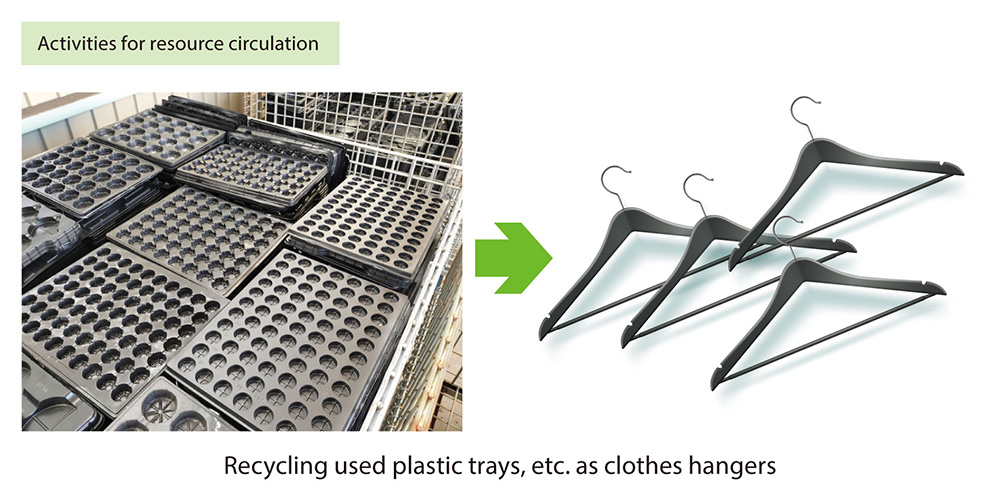

The “Act on Promotion of Resource Circulation for Plastics” was enacted in April 2022 to address the environmental impact of the increasing amount of marine plastic waste. In OHARA’s head office operations, 25% of the 60 tons of plastic waste generated annually is converted to material recycling for use in recycled plastic products.

The OHARA Group develops environmental conservation activities by quantitatively measuring the amount of energy and resources used in its business activities (INPUT), as well as the products and environmental loads generated by those activities (OUTPUT).

Solar panels are installed on the roof of the head office building, and some of the electricity is generated by our own power generation. Also called the No-Car Day Campaign, we encourage employees to commute by public transportation, on foot or by bicycle to reduce CO2 emissions. By setting the No-Car Day campaign date to the second Wednesday of every month, more employees are switching from commuting by car to commuting by foot or bicycle.

In Sagamihara City, where OHARA is located, the Sagami River flows and joins into the Sagami Bay. The “Sagami River Cleanup Operation”, organized by the “Love Sagami River Club” which protects the rich nature, and promotes the creation of a better environment, is held twice a year, where the cleanup of the entire river area is conducted.

environment education seminars were conducted for all employees working at OHARA. External experts were invited, and employees recognized the importance of basic knowledge on environmental laws and legal compliance, and the high level of interest in environment.

In April 2000, OHARA obtained certification under the international ISO14001 standard for environmental management (the certification body was JIC Quality Assurance Ltd.). We attained the environmental objectives and targets, and escalated environmental management systems through the Waste Reduction and Reuse Promotion Committee, the Resource Conservation Committee, the Energy Saving Promotion Committee, and environmental management activities at every department.

※The scope of application of the environmental management system is as follows. The environmental management system is applied to the head office and factory of OHARA INC. and its affiliated companies. ※In-house subcontractors collectively refer to contractors who are resident on our premises and who undertake the operations of our company or those who perform requested operations (repairs, maintenance services, etc.) within this factory.

Related information can be viewed by following the links below.

The things we focus on in manufacturing are explained.